Introduction

Equipment fault diagnosis plays an important role in building services, public utilities, transportations, manufacturing, and printing in industry. It represents productivity, product quality and life of machinery. However, the present diagnostic tools are complicated, expensive and incapable of detecting randomly occurred faults. Therefore, many failure warnings could be missed and ultimately, it leads to fatal breakdowns of equipment and human casualties. Smart Asset Maintenance System (SAMS) is composed of various state-of-the-art techniques for practical and effective equipment health monitoring and prognosis. SAMS is a low-cost, portable, versatile, and easy-to-use system that no other commercial system is comparable. It can perform equipment health monitoring either on-site or remotely via the internet, wireless or mobile communication. SAMS has been applied successfully in various machines operated in building services, public utilities, transportations, printing industry, and manufacturing

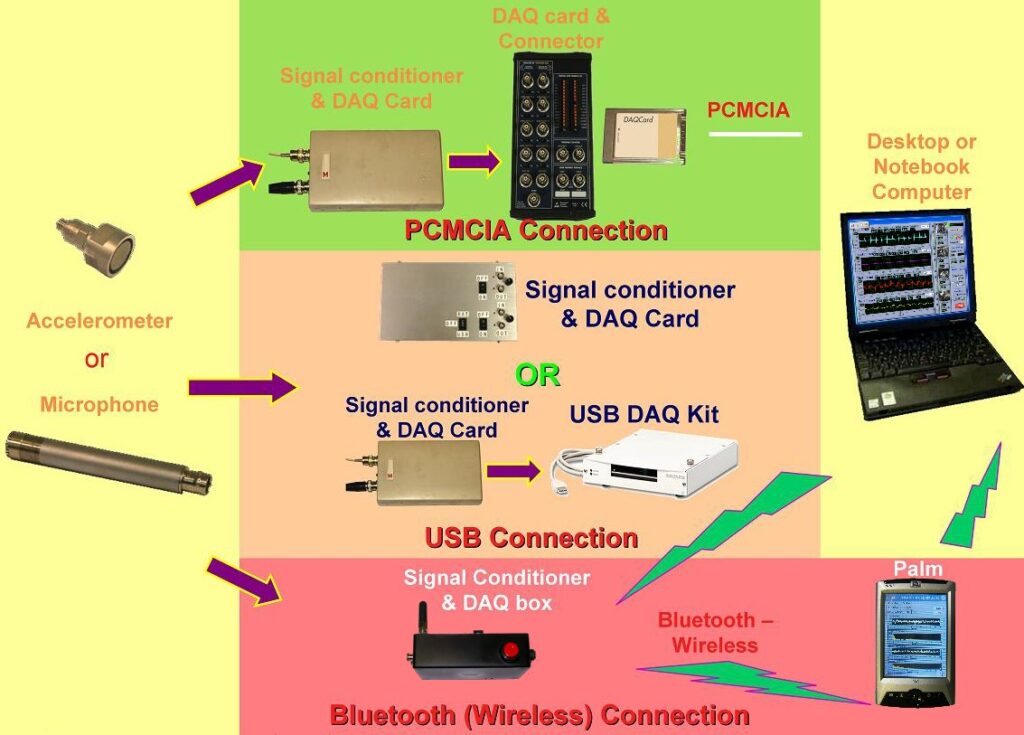

SAMS can be used with any 1 set of the following 3 combinations:

1) the USB kit

2) the PCMCIA kit

3) the Bluetooth wireless kit

The Connection of SAMS

SAMS is low-cost because it is implemented using a series of virtual instruments which are only 1/10 of the cost of existing hardware-based systems.

SAMS is embedded with the latest technologies in equipment fault diagnosis and prognosis. It can detect faults that exhibit not only periodic patterns but also random patterns which are not detected by ordinary vibration detection systems. SAMS provides advice on the intelligent equipment maintenance based on the current health condition of your equipment.