Aims

What is equipment health monitoring?

You certainly want to monitor the health condition of your equipment before they fail in service. Such failures may cause injury to people and major damages to your equipment. Ultimately, the damages may cause loss of production time and high recovery costs.

Equipment health monitoring is similar to the periodic health check that your doctor performs on your body in order to give advance warnings and advices for corrective actions.

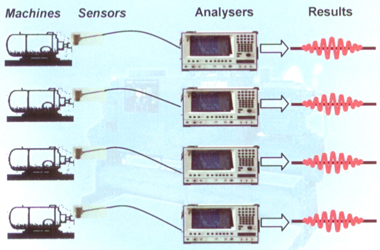

Equipment health monitoring employs many tools and technologies. Vibration analysis is a widely adopted tool in the industry because serious defects occurring in a machine will usually cause a significant change in vibration signal.

Reasons for using Remote Equipment Health Monitoring

Functions:

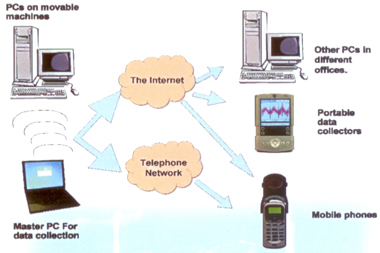

- Remote Condition Monitoring and Control remote sensing, access, and control of equipment.

- Remote Fault Diagnosis and Prognosis on-line equipment fault detection and remnant life prediction

- Collaborative Maintenance – instantaneous advices provided by world experts and equipment

Benefits:

- Use of Virtual Instruments – substantial savings in replacing hardware type of instrumentations

- Easy to modify and maintain – each virtual instrument has only one software copy installed in the main sever

- Transform Local Companies into Global companies – providing service to their customers anywhere and at anytime

- Accessible anywhere and at anytime via the internet wireless, and mobile communication